TS1000

TS1000

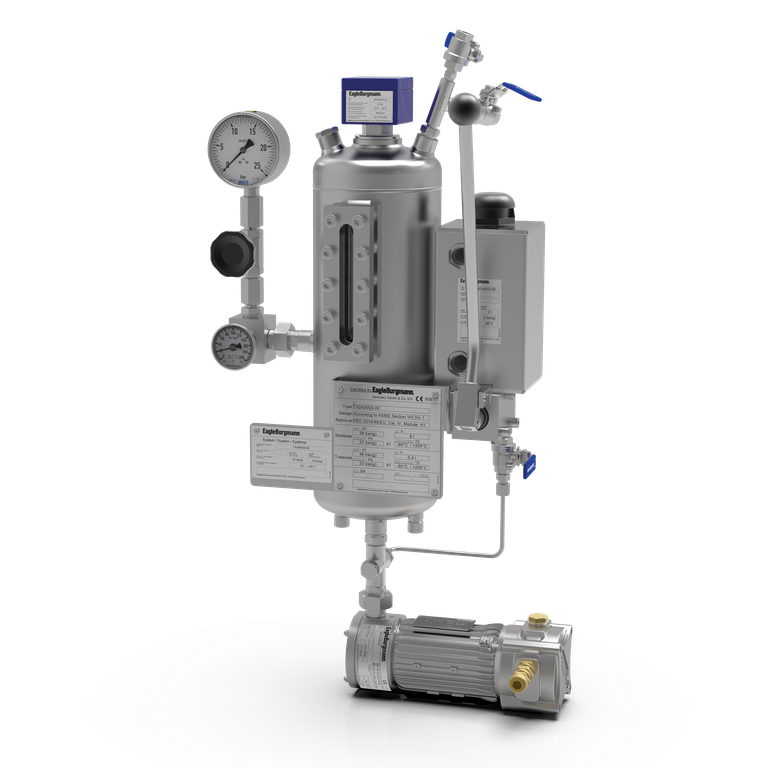

| Item | Description |

| 1 | Buffer/barrier fluid IN (G1/2") |

| 2 | Buffer/barrier fluid OUT (G1/2") |

| 3 | Cooling water IN (pipe 12 x 1.5 mm) |

| 4 | Cooling water OUT (pipe 12 x 1.5 mm) |

| 5 | Filling connection with cap (G1/2") |

| 6 | Pressure gas connection (1/4" NPT) |

| 7 | Connection for level switch (G2") |

| 8 | Connection for refill unit (G1/8") |

| 9 | Connection for pressure gauge (1/4" NPT) |

| 10 | Bracket for refill unit |

Dimensions for TS1016/A007

Values in brackets: TS1016/A003.

TS1000

Features

With the EagleBurgmann TS1016 thermosiphon system it is possible to supply buffer/barrier fluid to double and tandem mechanical seals for a broad range of applications. The TS1016 thermosiphon vessel is available with flat ends, sight-glasses for level monitoring and with cooling coil. TS vessels are equipped as standard with all the necessary system connections and brackets. The modular system allows the TS1016 vessels to be combined with a wide range of system components such as, e.g. level switch, circulation pump, hand refill pump, thermometer, base frame, etc.

Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A

Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A

Advantages

- Modular system: combination with a wide range of system components possible

- Vessel made of 1.4571 stainless steel / borosilicate sight-glasses: suitable for universal applications

- All system connections on the face sides

- Low space requirements because of compact design

Standards and approvals

- PED 2014/68/EU (Design and production in accordance with EU Pressure Equipment Directive)

- SELO, TR CU on request

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Chemical industry

- Petrochemical industry

- Pulp and paper industry

- Food and beverage industry

- Water and waste water technology

Functional description

The TS system performs all the basic functions of a buffer/barrier system for the operation of double seals:

- to pressurize the buffer chamber

- leakage compensation

- buffer/barrier fluid is circulated by thermosiphon effect or forced circulation system

- to cool the seal

- to selectively absorb product leakage and prevent dry running (tandem arrangement)

Product variants

| Designation | TS1016/A007 |

|---|---|

| Standard design | ◼ |

| Design code | PED 2014/68/EU |

| Integrated cooling coil | ◼ |

| Volume of vessel (liters) | 8 |

| Volume of tube (liters) | 0.2 |

| Allowable pressure¹ | 16 bar (232 PSI) |

| Allowable temperature¹ | -60 °C ... +200 °C (-67 °F ... +392 °F) |

| Working volume, MAX-MIN (liters) | 1.3 |

| Cooling capacity depending on process medium | (low flow / high flow) |

| Water | 1.4 kW2) / 1.9 kW3) |

| Ethylene glycol water (30:70) | 1.1 kW2) / 1.5 kW3) |

| Oil ISO VG10 | 0.3 kW2) / 0.4 kW3) |

| Metal parts | 1.4571 |

| Sight-glass | Reflex Borosilicate |

| Seal | PTFE |

Other versions on request.

1)Design data, permissible working values depend on the actual conditions of service.

2)Low Flow: 8 l/min (process fluid), 10 l/min (cooling water), △T = 40 K

3)High Flow: 15 l/min (process fluid), 20 l/min (cooling water), △T = 40 K

TS1016/A007

Similar products

TS3000

Thermosiphon systems of the TS3000 range designed specifically for the operation and supply of mechanical seals in sterile processes. The TS3000 thermosiphon vessel is available in two standard sizes, designed for dismantling, with cooling coil. The modular system allows the TS3000 vessels to be combined with a wide range of system components.

Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A

Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A

TS3016

The EagleBurgmann TS3016 thermosiphon system presents a simple and quick way to clean the vessel interior. For this purpose it is designed for easy dismantling. A quick-release coupling should therefore be used to connect the pressure gas to the vessel. The modular system allows the TS3016 vessels to be combined with a wide range of system components.

Circulation based on API 682 / ISO 21049: Plan 52, Plan 53A

Circulation based on API 682 / ISO 21049: Plan 52, Plan 53A

TSA2

- Successor of product lines TS2000, TS1020

- For ANSI pumps in chemical applications

- Pressure rating up to 25 bar(g) (362 psi)

- 40 % increased working volume compared to previous version

- Sight glass for level monitoring

- Cooling coil is supplied as standard

- All necessary system connections and brackets are provided as standard for optional components

- Circulation based on API 682 / ISO 21 049: Plan 52, Plan 53A